Mining

WITHOUT THE RADIATION

For Reliable Measurement, Smarter Optimization

+ Process Control

SIMPLE INSTALLATION

Installs inline with your existing pipe – no special tools, no major disruption.

MINIMAL MAINTENANCE

Just replace the cartridge when needed. Ruby software updates remotely, with no downtime.

LEGACY SYSTEM FRIENDLY

Integrates with your current setup – no need to rip and replace. We work with what you’ve got.

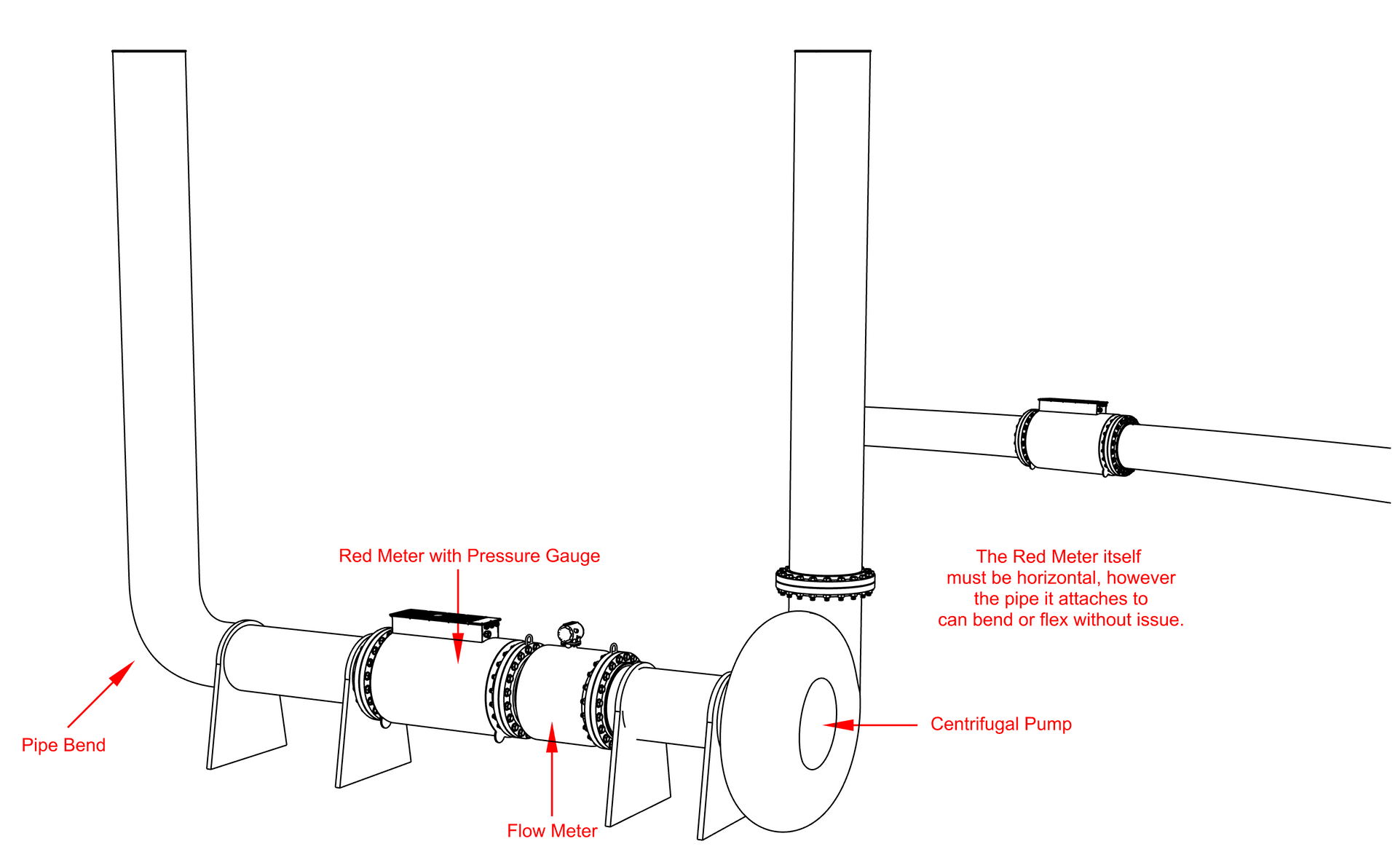

Below is an example of a typical installation of a Red Meter.

To design your optimal process with the help of a Red Meter, please Contact Us.

Simple, Yet Robust

Engineered for the realities of mining, the Red Meter delivers accurate, real-time Process Control data that helps process engineers fine-tune operations, reduce material waste, and keep systems running at peak efficiency.

With minimal maintenance and a straightforward inline installation, it’s a practical upgrade - not a project. There’s no radiation, no special handling, and no calibration drift to manage. Red Meters are built to run in abrasive, high-wear conditions where other instruments fail - and they don’t require a compliance officer to operate.

For teams tired of vendor overpromises and tools that don’t last, Red Meters offer something rare: proven performance, simple integration, and data you can actually use.