WHAT

DRIVES US?

Purpose, People & Precision,

Built into every Meter.

We believe that innovation should never come at the cost of safety, efficiency, or accuracy.

Our philosophy is rooted in the commitment to eliminate outdated, hazardous measurement technologies and replace them with smarter, non-nuclear, AI-driven solutions that empower industries to operate with precision and confidence.

We are dedicated to advancing industrial measurement through real-time process control, seamless cloud connectivity, and AI-powered insights. By focusing on innovation, integrity, and impact, we ensure that our technology not only meets today’s demands but also paves the way for a more sustainable, data-driven future.

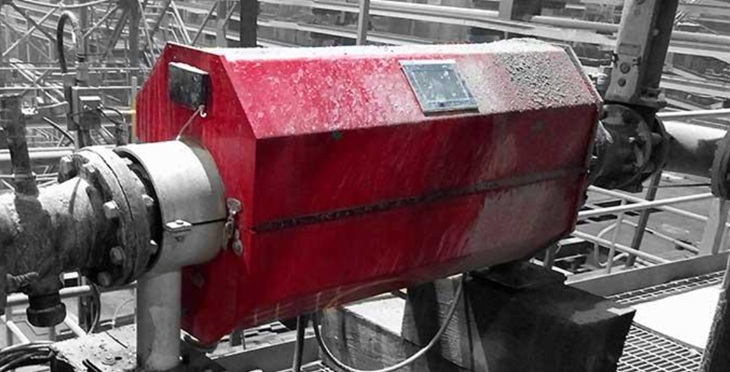

Every Red Meters system is handcrafted in the USA with precision, built to outperform expectations, and designed to optimize efficiency without compromise.

We believe in continuous improvement, customer-centric solutions, and pushing the boundaries of what industrial measurement can achieve.

At Red Meters, we don’t just measure - we redefine what’s possible.

Performance

+ Accuracy | ± 0.5%

+ Repeatability | ± 0.4%

+ Selectable Display Options

+ PIN-Secured configuration & calibration menu

+ Remote Interface (HMI)

+ Remote Support & Upgrades

+ Two 4-20 mA Outputs

Features

+ Density / Specific Gravity

+ Pressure

+ Flow Rate

+ Totalized Solids

Applications

Live data can be analyzed on any device simply using a web browser by Red Meters if there is a network connection.

Logged data can be exported via a USB stick from the meter directly. Exported data is in CSV format.

Patented Technology.

CONCEPTION

Innovation drives everything we do - Red Meters was born from a vision to revolutionize industrial measurement.

DESIGN

Precision-engineered and handcrafted in the USA, our technology is built for reliability, efficiency, and performance

ACCURACY

AI-driven real-time data ensures unmatched precision, eliminating guesswork and optimizing process control.

SATISFACTION

Designed for seamless integration and ease of use, our technology delivers results you can trust - every time.

Mission.

Method.

Momentum.

Our Experts.

At Red Meters, we are a small but dedicated team of innovators, problem-solvers, and industry specialists who work together to push the boundaries of density measurement technology. Our diverse backgrounds and areas of expertise allow us to approach every challenge with fresh perspectives and cutting-edge solutions. Whether it’s engineering, AI-driven process control, manufacturing, or customer support, we bring our collective skills to the table to ensure the highest standards of quality and performance.

While some of our team members prefer to stay behind the scenes, their contributions are just as vital to our success. At Red Meters, collaboration is at the heart of what we do, and we take pride in crafting solutions that are as reliable as the people behind them.

Timeline Milestones.

2016

Company Founded &

Patents Filed

Red Meters LLC was founded with a mission to revolutionize industrial measurement through innovative, non-nuclear technology. That same year, we filed our first patent for a proprietary inline measurement system - marking the beginning of a smarter, safer approach to density monitoring. This early milestone laid the foundation for what would become a patent-protected, AI-driven solution built to challenge outdated industry standards and deliver real-time process control that drives efficiency across sectors.

2017–2019

R&D, Beta Testing &

Market Validation

These years were dedicated to deep R&D, extensive market research, and refining the Red Meter technology through field-tested beta units. Early adopters in key industries helped validate performance and shape the product, laying the groundwork for a smarter, more durable measurement solution.

2020

Launch of TORO

Prototype Model

After years of intensive R&D, market research, and field validation, Red Meters released its first working prototype - the TORO model. Beta units were deployed across multiple industries, capturing real-time data in rugged environments and proving the durability and precision of our AI-driven technology. This milestone marked a major leap forward in delivering next-generation, non-nuclear density measurement with real-time process control at its core.

2021

Foundation Laid for

Rugged Design

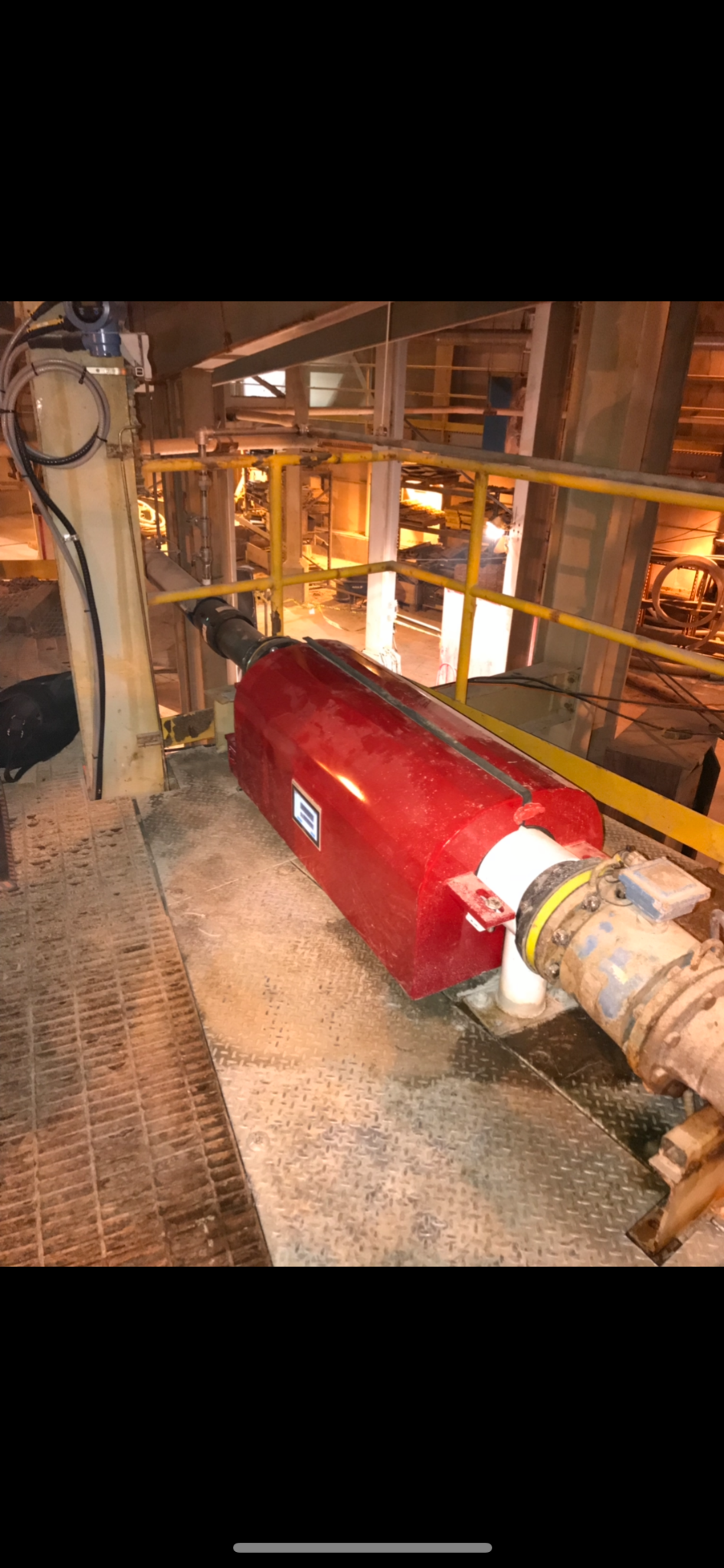

Red Meters entered a focused R&D phase to develop the Rugged Model. The team explored composite construction, refined adhesive selection, and began testing a range of liner materials to withstand highly abrasive applications. These foundational efforts set the stage for a more durable, flexible design built for real-world demands.

2022

Advancing Rugged

Full Redesign

Following extensive development, the Rugged Model underwent major engineering upgrades. Steel volume, overall size, and weight were reduced—streamlining installation without compromising strength.

Instrumentation was fully re-specified, and Ruby’s front and back-end software were rebuilt from the ground up. The result: a smarter, tougher, and more adaptable measurement system ready for modern industry.

2023

U.S. Patent Granted

IP Secured

Red Meters was awarded U.S. Patent #10,295,450, officially securing our proprietary technology for inline, non-nuclear density measurement. This milestone reinforces our commitment to innovation, accuracy, and industry leadership.

2025

Rugged Series™ 2.0 Ruby™ & Cloud Integration Launch

With the release of Ruby™ 2.0, Red Meters redefines AI-powered process control. This next-generation software delivers real-time visualizations, multi-sensor integration, and fully customizable displays - built on a more intuitive front-end and a robust back-end system.

Alongside software advancements, Red Meters introduced cloud-based monitoring, enabling remote access to live data, advanced logging, and enhanced AI compensation for dynamic process conditions. Ongoing R&D in flow insulation and instrumentation refinement further boosts accuracy and reliability in diverse environments.

As we expand globally across industries including oil & gas and dredging, Red Meters continues to lead the charge in non-nuclear, real-time industrial measurement.